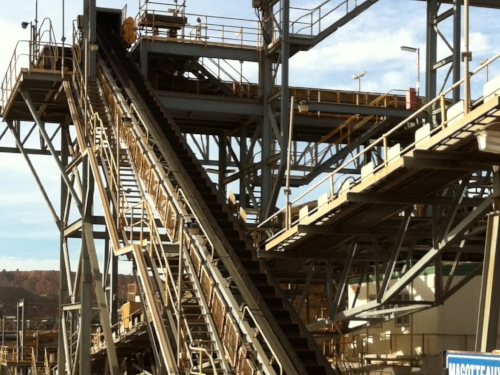

Our Chain Conveyors

Chain conveyors are a robust conveying solution with a vast array of advantages that many conveyors simply do not share.

Chain conveyors are generally used with a variety of materials but typically for products which are granular, very fine, where temperature is a problem (up to 1000°C), where changes in vertical direction are required or where multiple feed and/or discharge points are desirable.

Chain conveyors have many advantages over other conveyors. Being totally enclosed they pose no environmental problems and can be made dust- and/or water-tight as required. They are self-supporting and require no access alongside them. As a simple chain conveyor can operate in three planes it can be used instead of a horizontal conveyor, a bucket elevator and an elevated horizontal conveyor to deliver product over a combination of horizontal and vertical distances.

Economical Conveying

With the ability to incorporate vertical bends, chain conveyors can remove the need for multiple conveyors when needing to move a product both horizontally and vertically by providing a ‘Z’-style configuration. This single-conveyor option also has the added benefit of reducing overall power consumption and long-term operating costs.

Efficient Conveying

Conveying of product can be achieved through either the drag or ‘En-Masse’ principle. The ‘En-Masse’ principle is utilised when conveying product vertically or at steep inclines, in which the product is loosely compacted into a single column that moves seamlessly with the chain crossbars.

Clean Conveying

Chain conveyors are totally enclosed and inherently dust tight, removing the need for dust-prevention systems and wasted labour.

Click on the image to enlarge

Our Specialty

At Skilled Materials Handling we have designed, manufactured, supplied and maintained over 300 chain conveyors for over 60 clients worldwide. We are the premier choice in Australia for chain conveyors, and we are continuously searching for improvements so that we can deliver the best product to our clients.

Our Bucket Elevators

Bucket Elevators are the simple and effective solution for vertical conveying.

Simple but rugged, our Bucket Elevators are a cost effective method for transporting materials vertically in a continuous flow. Based on the application, we offer dependable operation through either belt or chain elevators whilst providing all the spare parts required to accommodate to your maintenance schedule.

SIMPLE CONVEYING

Our elevators are simple but durable, designed to optimise capital and operating costs. They are an excellent choice to transport materials vertically even for materials with difficult properties.

VERSATILE CONVEYING

We offer multiple choices in bucket shape, build material and configuration to suit your needs. We can make our elevators with either a centrifugal or central discharge system depending on your requirements.

MODULAR CONVEYING

Our Bucket Elevators can be upgraded to suit changes in your process, whether it is a change in conveying volume or a change in material to be conveyed we can assist you to modify and upgrade your unit to suit.

Click on the image to enlarge

OUR ROBUST SOLUTIONS

Offering both heavy duty and light duty bucket elevators, Skilled Materials Handling has a large volume of experience. With over 130 bucket elevators designed and manufactured globally, moving products that range from wet slag to cement, we are the premier choice for robust bucket elevators in Australia.

Our Screw Conveyors

Screw conveyors are an historically proven bulk material handling conveying equipment, providing both cost and simplicity benefits to the client.

Screw conveyors are amongst the oldest forms of conveying equipment devised, in ancient Greece Archimedes used the principle to lift water. Today their use extends to many diverse applications and for relatively short distances they are considered before anything else.

Screw conveyors are relatively compact and are suited for the transport of materials at any inclination. They are usually completely enclosed and can be made dust- and/or water- tight to avoid any environmental problems. Material can be transported with the same screw to different points. Additionally material can be transported alternatively in both directions by reversal or direction of rotation.

SIMPLE CONVEYING

When conveying is simple, capital and operating costs are low. Screw conveyors are inherently simple, and this results in screw conveyors being an excellent choice for short and low-capacity conveyors.

VERSATILE CONVEYING

Due to the many options available in screw flights, screw pitches, casing inclination and casing type, the screw conveyor is an incredibly versatile piece of conveying equipment.

FEEDER CONVEYING

Widely known as the leading choice for feeders, screw conveyors are uniquely suited for this application due to their effectiveness in agitating the material from below.

Click on the image to enlarge

Our Versatile Solutions

Focusing primarily on heavy-duty screw conveyors, Skilled Materials Handling has a large volume of information when it comes to robust screw conveyors. With over 125 screw conveyors globally that move products such as fly ash, brown coal, limestone, cement dust and cyanide, we have the experience to provide our customers with the best possible conveyor.

Our Alternative Conveying Solutions

Belt conveyors have become the market leader when it comes to simple and cost-effective conveying solutions. Due to their simplicity, belt conveyors see a very low level of maintenance when compared to most other conveying solutions. However, this simplicity also results in disadvantages and prevents this conveyor type being used in situations where spillage and dust management are a priority or where steep inclinations are required.

A superior alternative to two belt conveyors and one bucket elevator, the sidewall belt conveyor allows product to be moved in a ‘Z’-style configuration with reduced spillage. The belt has “sidewalls” and “bucket cleats” vulcanised onto the belt, which allows the “pockets” between cleats to act as enclosed buckets as the product is moved vertically.

Where design calls for the transport of hot, abrasive and large sized bulk materials, pan conveyors may be the preferred option. Pan conveyors come in three different options:

- Apron Feeders. Designed for high capacity and rugged service in applications such as dump hoppers and extracting materials from under bins, silos or hoppers.

- Pan Conveyors. Used generally over longer distances and can transport product horizontally and slightly inclined.

- Box Conveyors. Used when steeper inclinations are required, box conveyors can convey product when changes in inclination are required, resulting in a ‘Z’-style configuration.